crushing efficiency formula

Crusher Efficiency Determination | Crusher Mills, Cone Crusher, Jaw

Aggregate Screening and Crushing Equipment,Aggregate Screen Size Aggregate screening and crushing equipment is using industrial crusher and vibrating screen. Determination Of Required Screen Size. E = efficiency factor Determination of the Mining Business Area | Quartz Crusher Determination of the Mining Business Area.

Learn MoreCalculating the efficiency of crushing plant

An engineering efficiency analysis of the operation of plants for crns oversize rock fragments reveals that it is not altogether correct to assess their

Learn MoreDetermination of capacity of single-toggle jaw crusher, taking

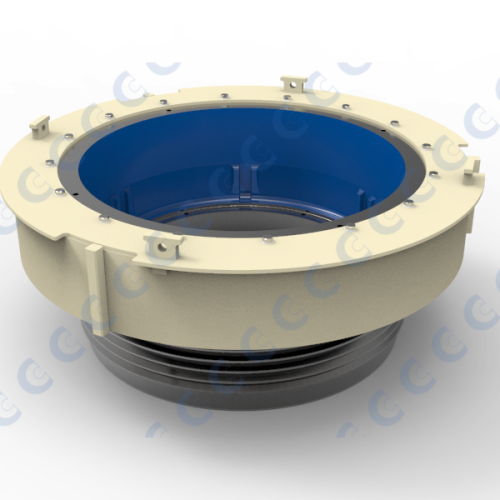

Abstract. Efficiency increase of jaw crushers makes the foundation of rational kinematics and stiffening of the elements of the machine possible.

Learn Morecrushing efficiency of a crusher

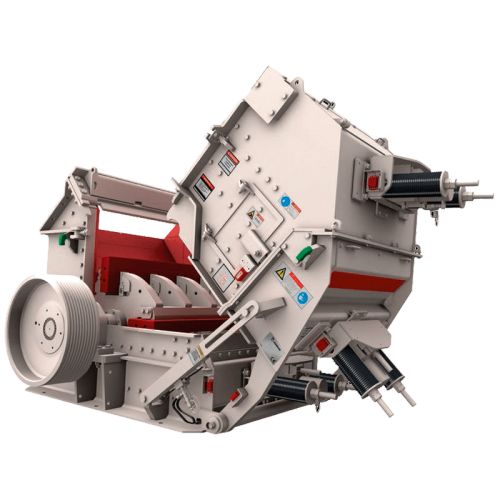

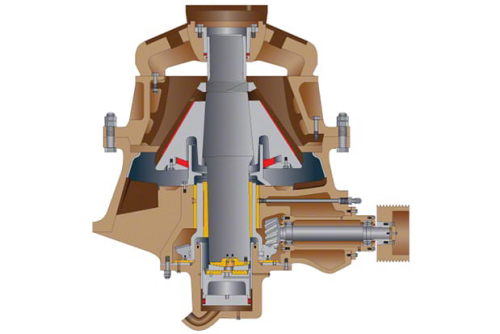

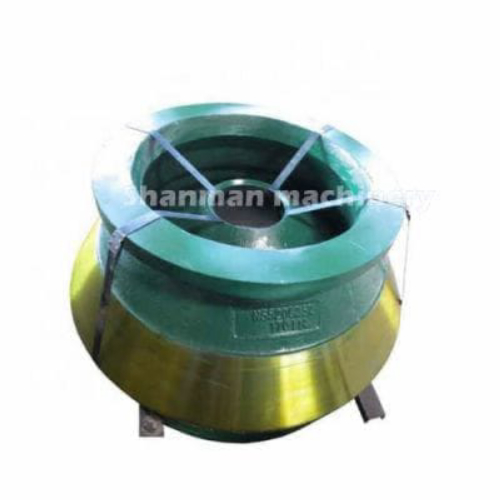

crushing efficiency of a crusher high efficiency cone crusher mantle germe edu.org ® HP Series™ cone crushers PFS Impact Crusher vipeakgroup.com Assessing the ene

Learn MoreMODELLING, SIMULATION AND OPTIMISATION OF ... - CORE

The motivation behind this was to determine the crusher efficiency at the time of feed sampling. Table 4.9 Particle size distribution of the crusher product. 02

Learn MoreScreen efficiency calculation - Crushing, Screening & Conveying

Screen efficiency is obtained using different equations, depending on whether your product is the oversize or undersize fraction from the screen. The following information is required to

Learn Morecrushing efficiency calculation equation

crushing efficiency calculation equation aug 2, as the equation for calculating the efficiency of a jaw crusher is a for to real jaw crusher performance rocks + calculating circulating load in crushing circuit pdf

Learn Morecrushing efficiency formula

Calculating Vibrating Screen Efficiency Crusher Screen Plate. Calculating Vibrating Screen Efficiency Crusher Screen Plate. screen, circular or reciprocating, or with aponent, or it may be a vibration applied directly to the screen wires.3 In the example above, the

Learn MoreArea of Product giving Crushing Efficiency Calculator

The Area of Product giving Crushing Efficiency is the area of the output particles that is reduced by the crusher and is represented as Ab = ( (ηc*Wh)/es)+Aa or Area of Product = ( (Crushing Efficiency*Energy Absorbed by Material)/Surface Energy per Unit Area)+Area of Feed.

Learn MoreFormula Of Crushing Efficiency

definition, efficiency equation, examples,thus, we can calculate the efficiency by using the formula as below: × 100%. = × 100%. = 0.40 × 100%. = 40%. therefore, we see that the efficiency of the hammer strike was 40%. vibrations and heating of the nail are two potential causes for the loss of energy. question- a certain process of the chemical has an energy efficiency of just 3.00%

Learn MoreMINERAL PROCESSING LABORATORY MANUAL - VSSUT

Crushing of Ore in a roll crusher, and Determination of average size by sieving. 16-18. 7. To determine the reduction ratio, theoretical capacity,

Learn MoreTips for maintaining efficiency in crushing circuits - Quarry

Crushing setting: Efficiency The reduction ratio is then calculated by comparing the input feed size passing 80 per cent versus the discharge size that passes 80 per cent. The finer the CSS, the greater the proportion of fines produced.

Learn MoreEfficiency Of Crusher Formula - RISE

Efficiency Formula For Crusher. Efficiency formula for crusher crusher efficiency has a huge influence on productivity they also offer far better iron liberation in concrete recycle work than do jaw crushers mantovanibenne a tool for all reasons concrete crusher crh440 the crh demolition crusher is dedicated for primary demolition

Learn MoreCrushing Efficiency Calculator

Crushing Efficiency calculator uses Crushing Efficiency = (Surface Energy per Unit Area*(Area of Product-Area of Feed))/Energy Absorbed by Material to calculate

Learn MoreEnergy requirements in size reduction of solids - CORE

2) the efficiency decreases from crushing to grinding steadily; the upper most point 'p' representing 25% and lower most point indi- cating 0.02%. This lowest

Learn MoreCrushing Efficiency Factors - Mineral Processing & Metallurgy

single layer particle crushing was taken to be 100% efficient, and measurements were made of the relative efficiencies, i.e., the ratio of the amounts of energy required to achieve the same degree of plate separation in crushing the multi-layer particles to reduction ratios of 1.16, 1.28, and 1.40 (the reduction ratio is defined as the separation

Learn MoreSize reductim of Solids

crushing efficiency range: 0.001 to 1%. The quantities needed for calculation of efficiency: i) Total energy input, ri) energy lost during size reduction.

Learn MoreImpact Crushers Design And Calculations

Productivity size is the most direct response to the equipment production efficiency, therefore all the operators have to do statistics and analysis of daily, promptly to the crusher productivity effectively adjusted, in order to adapt to the different intensity of production demand. The calculation of the motor power

Learn MoreCrushing Efficiency Formula Of A Ball Mill

Crushing efficiency The formula is the same for the rod mill and the ball mill, but that for ball mills is probably more reliable. ball milling, vibration milling, and plate (pan or plane) milling. Ball milling is typically loaded with particulate materials at its 30%–40%

Learn Moreformula of crushing efficiency

3 Crushing Efficiency Calculation Equation, Jaw Crusher Crushing Efficiency Calculation Equation. Jaw crushing efficiency calculation equation 20171025crushing machine production capacity calculation farmula 20 x 36 cedar rapids jaw crushers capacity calculation crusher news formula to calculate ball mill efficiency manganese crushercalculation of the click chat now

Learn MoreThe determination of the efficiency of the milling process

The results of slow crushing tests in a stiff testing machine for both small and large step reductions of particle size are given. The energy consumption.

Learn More

Leave a Comment